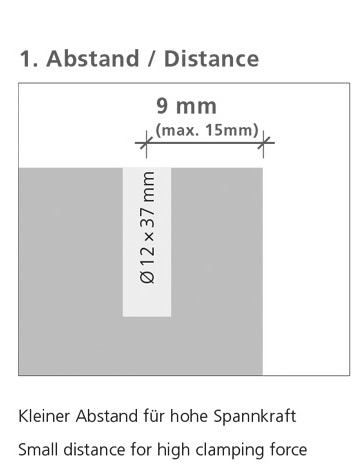

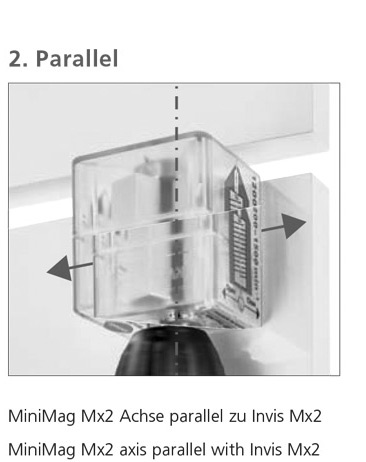

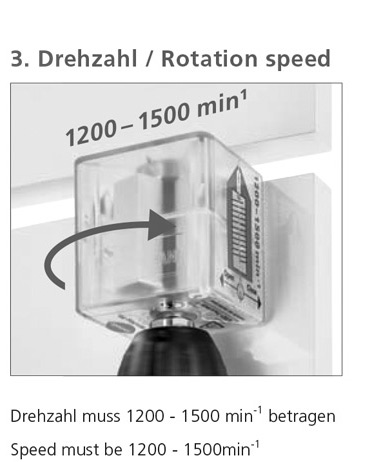

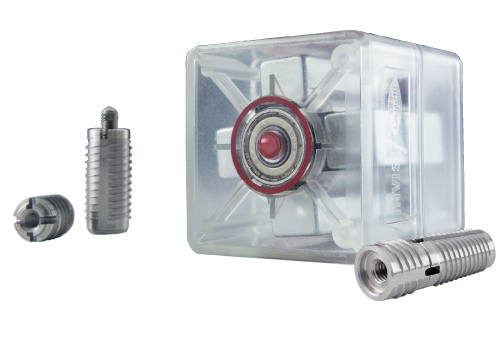

This is the principle that makes everything possible. The rotating magnetic field of the Mx2 Minimag/ actuator drives the joining element just as one cogwheel drives the other. The screw within the joining element threads itself into the inside thread of the stud which is driven by the contact-free magnetic field to ensure a tight connection. The Mx2 Minimag is attached to any standard drill with 1200-1500 RPM. The impact wrench effect of the INVIS fastener produces a knocking sound at the end of the screwing process (after approx. 5 seconds). This indicates that the connection is closed and also ensures amazingly high tightening values. To open the connection, the rotation of the actuator is reversed. It is held once again on the drill parallel to the fastener axes and the joint is opened without contact.

Main Features

The Economic Benefit of INVIS

INVIS has all the advantages of a dowel connection: time-saving, simple drilling. Production and assembly is performed quickly whether in the factory or on the spot. The INVIS actuator connects and detaches conveniently from outside.

| Easy | ||

Visible rotation in the Mx2 Minimag indicates if the connection is opening or closing. Visible rotation in the Mx2 Minimag indicates if the connection is opening or closing. |

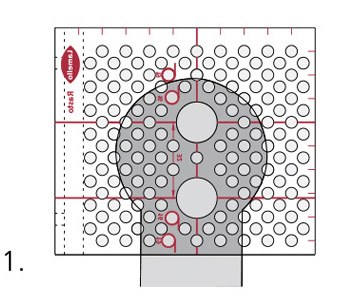

The red arrow displays the correct positioning of the cube on the work piece. The red arrow displays the correct positioning of the cube on the work piece. |

Increased tolerance enables simplified handling during installing. Increased tolerance enables simplified handling during installing. |

| Efficient | ||

Better handling- the double threaded elements allow the installation of Mx parts straight and quickly. Better handling- the double threaded elements allow the installation of Mx parts straight and quickly. |

No drill or bit changes are required. The same screw bit is used for the element and the stud (mail and female). No drill or bit changes are required. The same screw bit is used for the element and the stud (mail and female). |

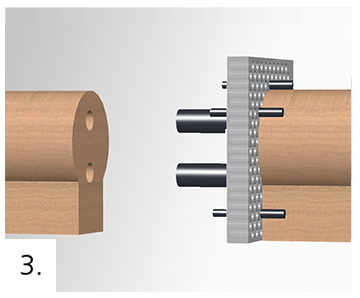

The joining element and the stud can be mounted flush for easy stacking and for a slide-in assembly. The joining element and the stud can be mounted flush for easy stacking and for a slide-in assembly. |

| Powerful | ||

A 50% larger magnet results in powerful clamping of the joint. A 50% larger magnet results in powerful clamping of the joint. |

A 35mm long metal thread allows strong anchors – very useful in particleboard. A 35mm long metal thread allows strong anchors – very useful in particleboard. |

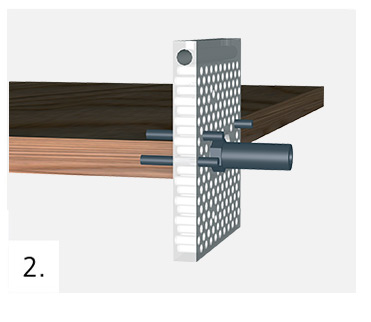

Flexible shaft on the Mx2 MiniMag: ideal angle drive, now Invis can reach the smallest corners. Flexible shaft on the Mx2 MiniMag: ideal angle drive, now Invis can reach the smallest corners. |

Installation

The Practical Advantages of INVIS

The INVIS actuator is the practical magic wand of the system. It is extremely simple to use: place the actuator on work parallel to the joiner, tighten the joiner approximately five seconds, that’s all there is to it! The tapping sound indicates that the joiner has tightened. To detach follow same procedure reversing the INVIS rotation.

- The Mx2 MiniMag is an adaptor that attaches to any stardard drill with 1200-1500 RPM.

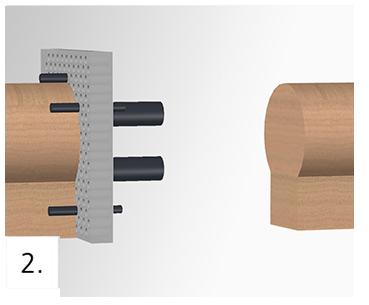

- The rotating magnetic field of the Mx2 MiniMag drives the joining element just as one cogwheel drives the other.

- The screw within the joining element threads itself into the inside of the stud- driven by contact-free magnetic field.

- To open the connection, simply reverse the direction of the drill.